High Specification Components

The use of high specification components and materials enables the operation of the Manifolds in a variety of environments and functions. The Manifolds are suitable for installation within a pressure compensated oil-filled enclosure or open to the external environment up to depths of 3000m.

Port positions, connection type and component layouts are all configurable to enable installation in a variety of orientations to fit the available space. Supply and function lines can be installed with dual pressure transducers for added redundancy should this be required on any of our Manifold designs. The Manifolds can be fully ported or mount onto a base interface. Manifolds can be daisy chained to give increased functionality or to mount clusters of valves closest to their functions thus reducing multiple complex equipment tubing runs.

We can rapidly configure manifolds for a variety of uses.

Initially designed for use in our Subsea Control Module (SCM), the flexibility of designing using Solidworks 3D and Enterprise configuration management software, allows us to rapidly configure manifolds for a variety of uses. The individual Manifolds can be deployed Subsea as part of a range of equipment such as an SCM, intervention tooling package or Subsea Isolation Valve (SSIV) control assembly.

Bespoke designs can also be catered for.

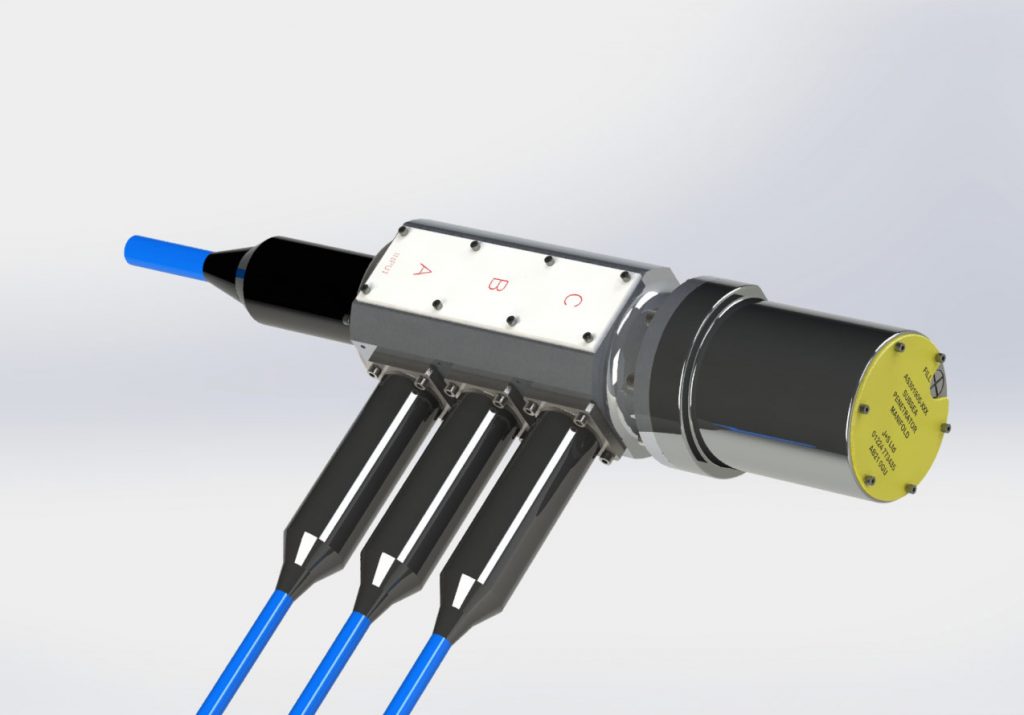

Subsea Penetrator Manifold

J+S has designed a highly survivable Subsea enclosure.

Maintenance-Free and Secure

The Subsea Penetrator Manifold is suitable for use as a junction box, electrical termination/distribution module or secure housing for electrical components.

The Subsea Penetrator Manifold provides a maintenance-free and secure subsea enclosure utilising J+S’s extensive capability in high integrity vessel design and manufacture. The Subsea Penetrator Manifold can be used in numerous applications and has a wide range of interfacing options. These include subsea connectors or an over moulded stainless steel penetrator, providing a versatile interfacing solution for multiple subsea connection points.

Key Features

- Oil or gel filled housing

- Polyurethane mould penetrator using proven technology

- Constructed in alloy or 316L stainless steel for excellent corrosion resistance

- Qualification tested to depth of 300m

- Internal splicing using proven polyurethane moulding technique

- Multiple connection ports (dependent on size of housing)

- Multiple connection types (subsea connectors, moulded penetrator, etc.)

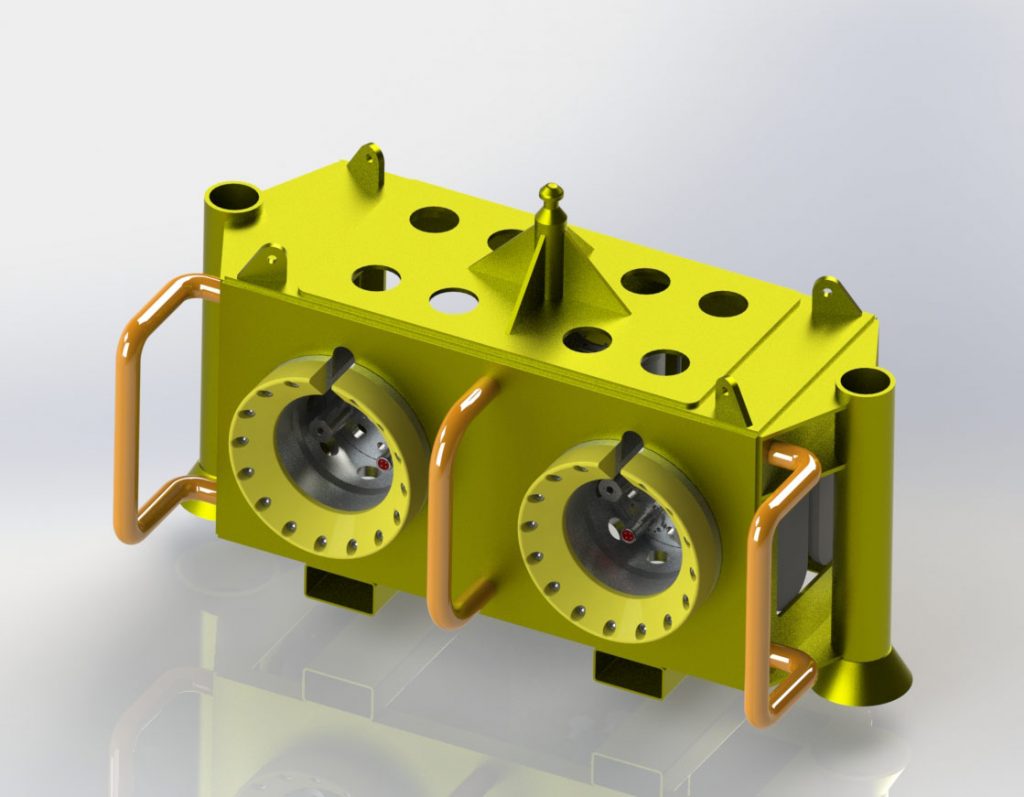

SSIV Hydraulic Manifold

J+S has designed a manifold that mounts direct immersion subsea directional control valves, suitable for single acting actuator functions.

Hydraulic Latching

The SSIV Hydraulic Manifold valves are designed to hydraulically latch when a pulse signal is sent to move to the valve to the open position. The valve will remain latched until a close signal is received or the hydraulic pressure drops below a pre-set value. On close the function line is vented locally. Manifolds can be configured for single or multiple DCV’s. Function line pressure transducers are incorporated mounted directly to the DCV to provide indication of system status.

Key Features

- Maximum Operating Depth of 3000m

- Weight 6 Kg

- Max Dimensions of 0.3m x 0.19m x 0.15m

Supply and Filter Manifold

J+S has designed a supply and filter manifold for full immersion and can be used as an independent or combined in-line filter assembly.

Dual Redundant Inputs

The Supply & Filter Manifold combines dual redundant inputs via an integral shuttle valve through a filter to provide a single clean output. The filter housing contains a stainless steel mesh filter element. Supply line pressure transducers are incorporated to provide indication of system status.

Key Features

- Maximum Operating Depth of 3000m

- Weight 8 Kg

- Max Dimensions of 0.25m x 0.12m x 0.1m (Various filter length options)

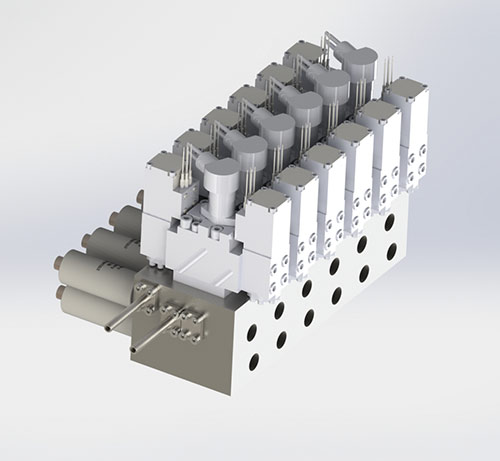

Tooling DCV Manifold

J+S has designed a tooling DCV manifold suitable for double acting actuator functions.

The valves are designed to remain in set position until a pulse signal is sent to move to the opposite setting. Manifolds can be configured for multiple DCV’s. The Manifolds can also be combined by connecting in series to give various combinations to meet system requirements. E.g. A 22 DCV system with 4 Manifolds set at different locations on a tooling skid laid out as follows; 4-station + 6-station + 8-station + 4-station.

Key Features

- Operating depth of 3000m

- Weight 36Kg

- Max Dimensions of 0.4m x 0.25m x 0.18m (0.4m x 0.25m x 0.3m with Transducers)

- J&S Subsea Limited

-

Holland House

Pitmedden Road

Dyce

AB21 0DP - T: +44 1224 773435

- E: [email protected]

- Registered in Scotland No : SC645331