Across the subsea industry, companies face a growing challenge. Assets are aging, original equipment manufacturers (OEMs) are no longer supporting older critical parts, and lead times for new components can be excessively long. For operators, decommissioning teams and service companies these delays can mean project disruption, rising costs, and unnecessary waste.

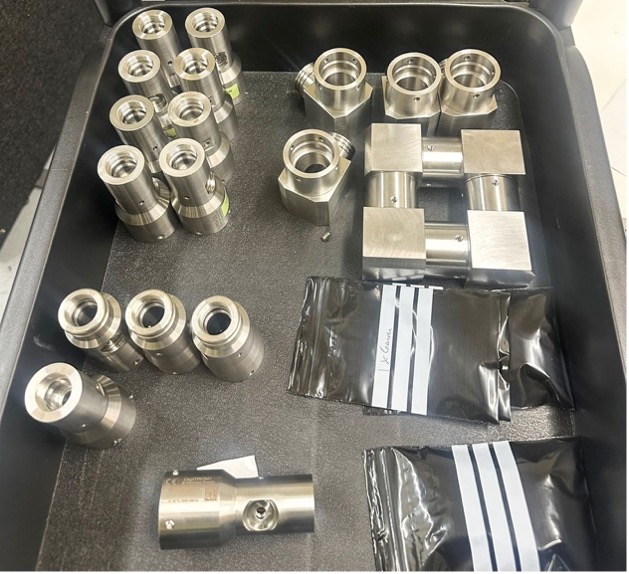

(Legacy Locker equipment ready for deployment. Supporting operators with immediate access to critical subsea components.)

J+S Subsea created Legacy Locker to provide a smarter solution. By stocking and recertifying vital subsea equipment, the service helps operators maintain late life assets, reduce downtime, and extend the value of existing investments.

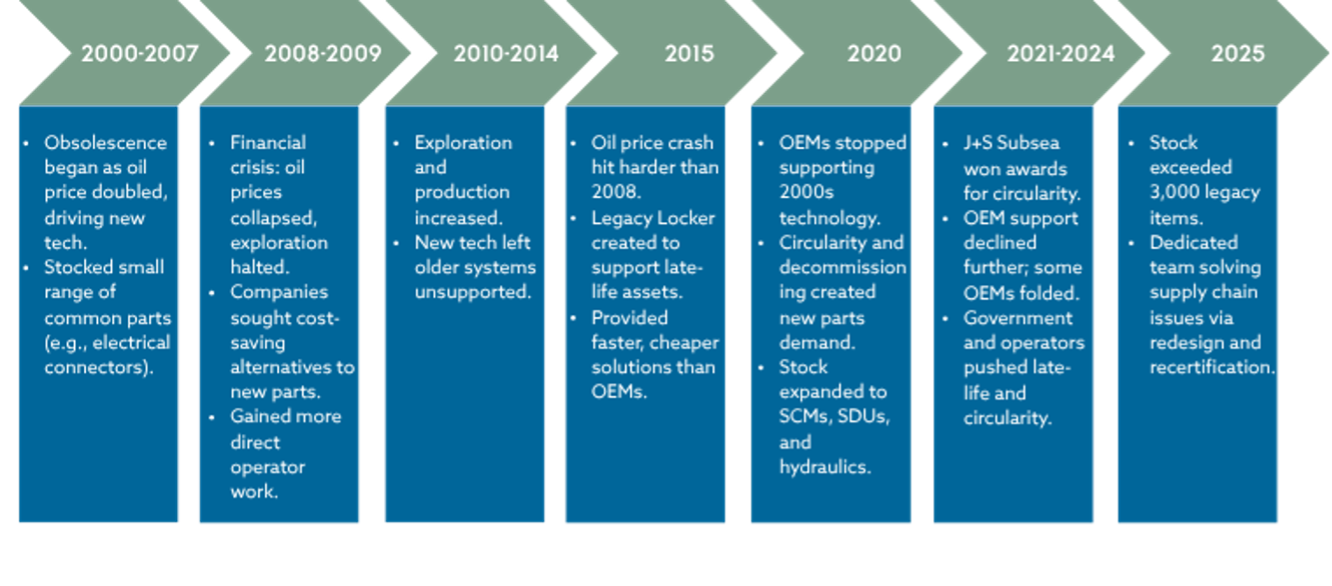

A Solution Shaped by Industry History

The story of Legacy Locker began long before its official launch.

- In the early 2000s, new technology fuelled a boom in the North Sea. Investments grew rapidly, but obsolescence soon followed as supply chains struggled to keep pace.

- The 2008 financial crisis and 2015 oil price collapse forced operators to maintain equipment rather than replace it. Companies faced longer lead times and limited support from OEMs.

- By 2020, with OEMs no longer supporting technology from the 2000s and environmental drivers pushing for circularity, J+S Subsea’s management buyout created the opportunity to formally launch Legacy Locker.

Since then, the initiative has grown rapidly, receiving industry recognition for helping companies adopt more sustainable approaches to asset management and recertification.

How Legacy Locker Works

Legacy Locker is not a brokerage. Operators get recertified, warranted usable parts, not untested second-hand resales. Unlike resellers, J+S Subsea also works directly with clients to help extend the lifecycle of their equipment.

- When operators no longer need specific equipment, J+S Subsea takes ownership and brings it into the Locker so that it can support other projects.

- Partners with inventory management and decommissioning companies to ensure valuable equipment is preserved, not sent to landfill.

- A dedicated team works with clients to manage redesign, recertification, and remanufacture, ensuring every item meets operational requirements.

This approach not only solves challenging problems but also supports the wider circular economy.

What’s Inside the Locker

Today, Legacy Locker stocks more than 3,000 items ready for deployment. Examples include:

- Electrical Connectors

- Hydraulic Couplers

- Subsea Control Modules

- Electrical Distribution Units

- Subsea Distribution Units

- Hydraulic Power Units

- Control System Specialised Test Equipment

|  |  |

Who Benefits

Legacy Locker supports a full range of subsea stakeholders. Operators, vessel contractors, service companies, and decommissioning teams can all access urgent or planned solutions through the Locker.

When subsea equipment first arrives, it can often carry the marks of service life offshore. Items are thoroughly cleaned to remove marine growth and contaminants before undergoing a structured process:

- Inspection – detailed checks to assess condition and identify any damage.

- Cleaning and refurbishment – restoring equipment, replacing parts where necessary, and preparing it for testing.

- Testing and certification – functional, electrical, and pressure testing ensures components meet operational standards.

- Stocking – only once verified is the equipment catalogued and added to the Legacy Locker inventory, making it ready for rapid deployment.

This process ensures every item in Legacy Locker is reliable, certified, and fit for purpose. Whether it is an urgent replacement to keep production running or part of a long-term asset life extension plan, clients can trust that equipment has been through a rigorous quality journey before reaching stock.

Results in Action

Earlier this year, J+S Subsea was contracted by a North Sea operator to repair four damaged 9-way MCE connectors on two stabplates. The connectors had been incorrectly installed into 7-way MCE parking connectors, causing bent pins and critical damage.

A dedicated J+S team mobilised to the Port of Aberdeen, South Harbour with all necessary equipment. Damaged inserts were removed and replaced using Legacy Locker inserts, ensuring immediate compatibility and avoiding reliance on OEM supply. This was a decisive advantage, as replacement connectors from the OEM carried a quoted lead time of more than nine months.

Comprehensive testing, including helium leak testing, continuity resistance, and insulation resistance, was carried out. Once verified, the repaired connectors were gel-filled, reinstalled into the stabplates, and restored to service within four days.

The outcome was clear:

- Operations were restored quickly, avoiding extended downtime.

- Legacy Locker provided immediate access to compatible parts.

- Collaboration ensured a complex subsea repair was completed on time and to full functionality.

Driving Circularity in Subsea

Legacy Locker is more than an equipment store. It represents a shift in how the subsea sector manages assets. By reducing waste, enabling reuse, and extending lifecycles, the service supports both operational efficiency and sustainability goals.

As legislation and industry standards increasingly push for circular solutions, Legacy Locker provides operators with a practical way to meet these requirements while keeping projects on track.

Find Out More

Legacy Locker continues to grow, with over 3,000 stocked items and a dedicated team focused on keeping subsea assets in operation.

Explore Legacy Locker today or contact our team to check stock availability or discuss your project needs.