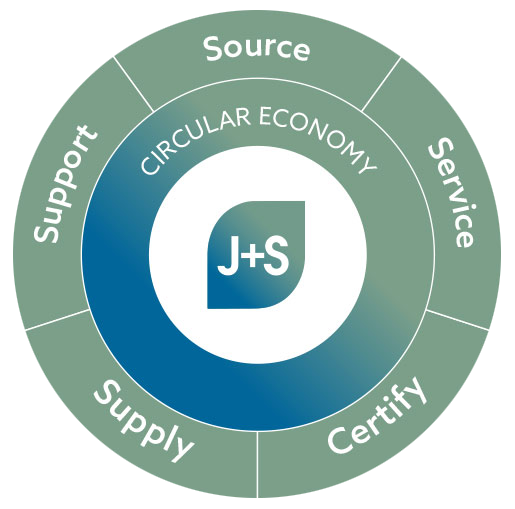

Circular Economy

We are committed to the circular economy and minimising the use of resource inputs and the creation of waste, pollution, and carbon emissions. Our aim is to provide continued support for legacy systems in order to keep products, equipment and infrastructure in use for longer, thus improving the productivity of these resources.

Source

Alternative sources for materials before new manufacture options.

Service

Service existing equipment and extend its life to reduce unnecessary manufacture.

Certify

Assembly and testing of all equipment to appropriate industry standard and original quality requirements.

Supply

Supply options to our clients for their existing equipment.

Support

Support our clients and utilise circular economy principles in our business.

Decommissioning Services

We mitigate premature decommissioning costs through comprehensive obsolescence management and legacy support. Our approach addresses traditional supply chain shortcomings by delivering timely, high-quality, and cost-effective maintenance solutions.

Our key services encompass:

Key services include >>

- Real-Time Monitoring of Pressure and Temperature in Abandoned Wellbores

- Safe Handling, Processing, and End-of-Life Disposal of Retrieved Subsea Infrastructure

- Specialist Engineering and Tooling Support for Offshore Well Intervention Campaigns

- Design, Supply, and Operation of XMT Hydraulic Flushing and Control Skid Packages

Refurbishment Services

We mitigate premature decommissioning costs through comprehensive obsolescence management and legacy support. Our approach addresses traditional supply chain shortcomings by delivering timely, high-quality, and cost-effective maintenance solutions.

Our key services encompass:

Key services include >>

- Bespoke precision reverse Engineering of Legacy Components and Systems

- Detailed Fault Diagnosis & Root Cause Analysis

- The legacy Locker supports urgent requirements, including sourcing and replacing obsolete components.

- Adapting Legacy Equipment for Modern Applications

- J&S Subsea Limited

-

Holland House

Pitmedden Road

Dyce

AB21 0DP - T: +44 1224 773435

- E: [email protected]

- Registered in Scotland No : SC645331